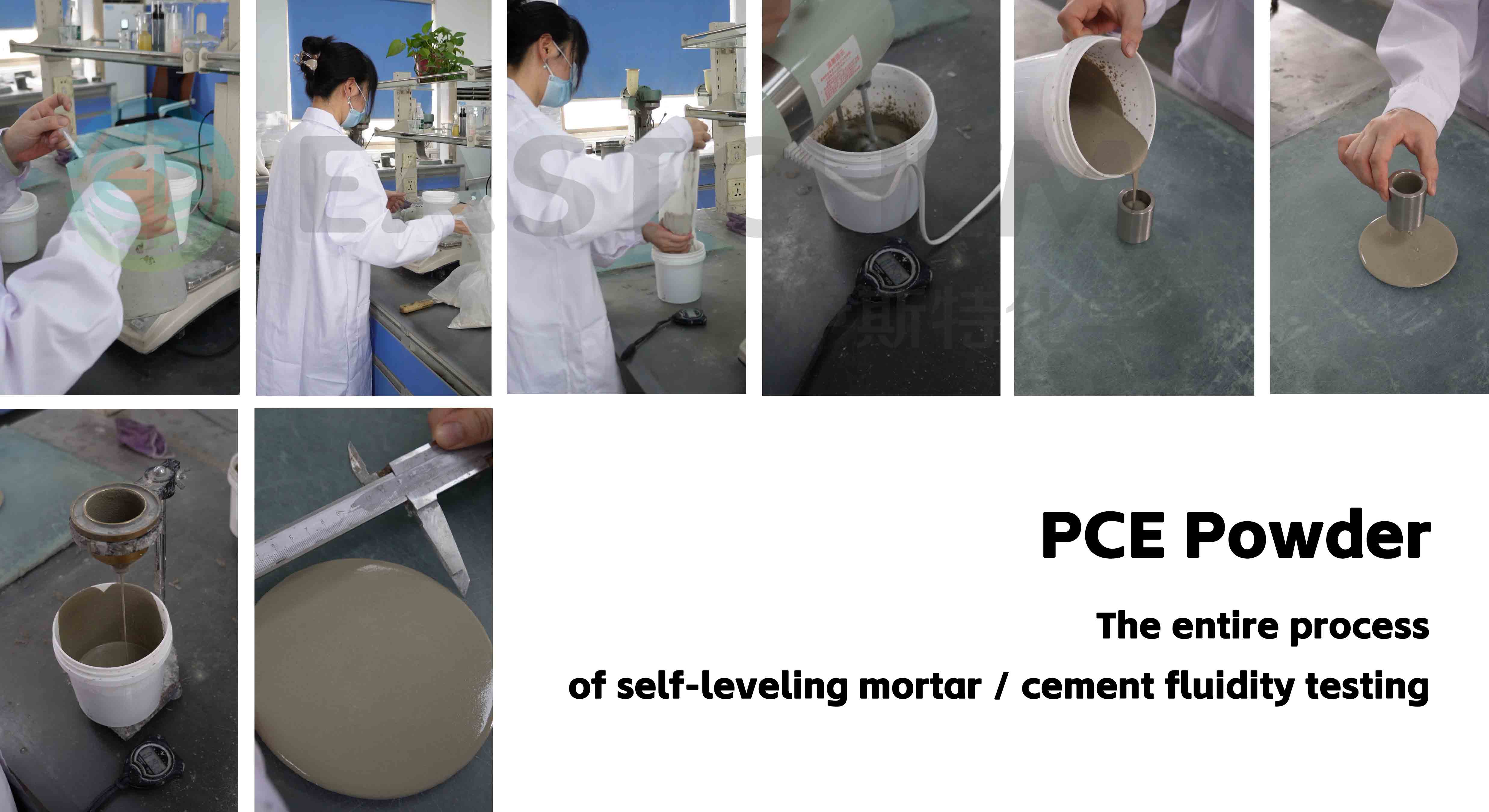

Application Case: High-Performance Polycarboxylate Superplasticizer in Ultra-Flow Self-Leveling Mortar

A major construction material manufacturer focused on developing high-standard, fast-track Cement-Based Self-Leveling Mortar (SLM) for flooring applications.

Traditional mortar formulations required excessive water to achieve self-leveling flowability. This high water-to-cement ratio (W、C) led to reduced strength, shrinkage cracking, and segregation issues. The client urgently required a high-performance water-reducing admixture capable of boosting the mortar's flowability to above $ text{280 mm}$ while maintaining a critically low W、C ratio, meeting the demands of ultra-flow construction.

Solution and Technical Parameters

Our technical team provided a customized high-performance polycarboxylate superplasticizer solution tailored to the client's mortar system (cement, fine aggregates, gypsum, etc.). This admixture was engineered for exceptional dispersion and slump retention capabilities.

Key Technical Metric Comparison

| Performance Metric | Control Group (No Superplasticizer) | Target Standard (With High-Performance PCE) | Performance Improvement |

| Initial Flowability | $ approx 150 text{ mm}$ | $ mathbf{295 pm 5 text{ mm}}$ | Significant Increase (Ultra-Flow achieved) |

| Water-to-Cement Ratio (W、C) | $0.45$ | $ mathbf{0.28}$ | Reduction of approx. $38 %$ |

| 28-Day Compressive Strength | $40 text{ MPa}$ | $ mathbf{55 text{ MPa} uparrow}$ | Strength Increase of $37.5 %$ |

| Slurry Stability | Prone to bleeding and segregation | Stable and Homogeneous, No Bleeding | Ensured uniform floor quality |

Mechanism (Core Function of the Admixture)

The high-performance polycarboxylate superplasticizer utilizes its unique comb-like molecular structure to effectively adsorb onto the surface of cement particles, generating strong electrostatic repulsion and steric hindrance. This action disperses the cement particle agglomerates, releasing trapped free water, which consequently:

Drastically reduces the water demand of the system, achieving High Water Reduction.

Significantly enhances the mortar's initial flowability and pumpability.

Maintains system stability after flowing, preventing the segregation and bleeding commonly seen in high-flow traditional mortars, ensuring the homogeneity of the final flooring.

Application Results

By incorporating our high-performance polycarboxylate superplasticizer, the client successfully resolved critical performance bottlenecks in their ultra-flow flooring mortar, leading to the following major benefits:

Improved Construction Efficiency and Quality: The mortar achieved a true self-leveling state, significantly minimizing manual leveling efforts and increasing construction speed. The resulting floor surface quality and flatness were superior.

Optimized Material Performance: The low W、C ratio, maintained despite the ultra-high flowability, led to a substantial increase in the floor's early and final strength, mitigating the risk of shrinkage cracking and reducing long-term maintenance costs.

Enhanced Market Competitiveness: The client was able to develop a premium flooring product meeting the highest industry standards, enabling them to secure high-value commercial and industrial construction projects.