The Role of High-Flexibility RDP in Underfloor Heating Systems

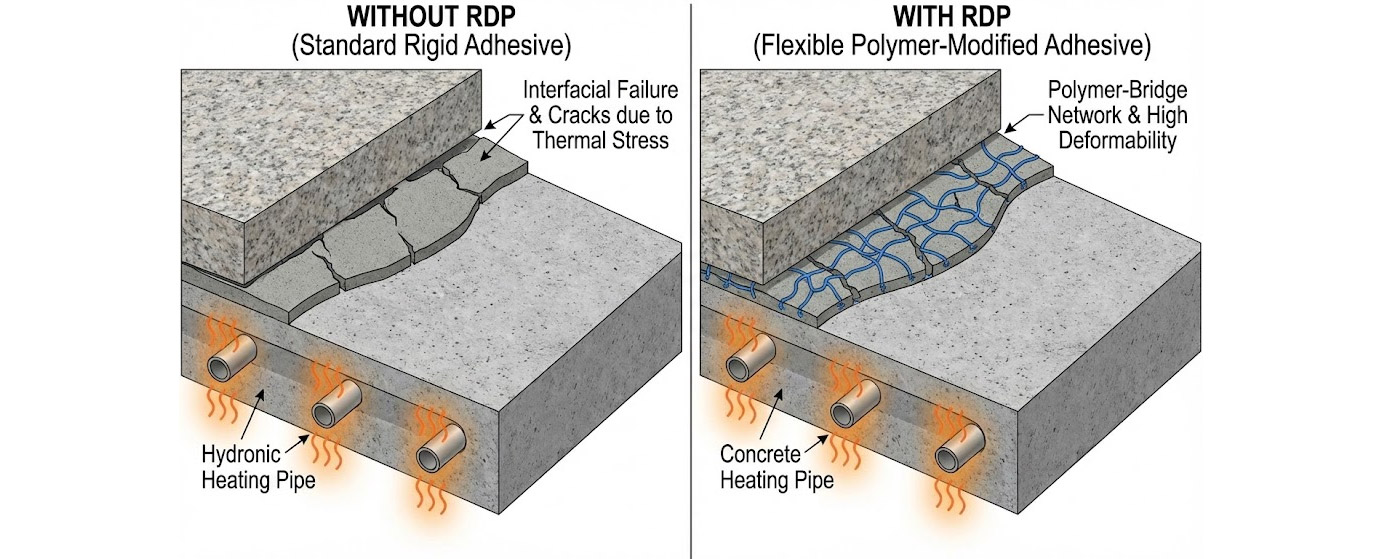

2026-01-30 16:44The rapid adoption of underfloor heating systems in modern residential and commercial construction has shifted the technical requirements for tile adhesives. Unlike standard environments, heated floors subject the adhesive layer to constant thermal expansion and contraction. Without the intervention of a high-performance flexible tile adhesive additive, the rigid bond between the substrate and materials like granite or ceramics is prone to shear failure, leading to "hollow" tiles or catastrophic debonding.

The Challenge: Thermal Deformation and Elastic Modulus

Granite and large-format ceramic tiles possess high density and low water absorption. When the heating system is activated, the temperature gradient creates internal stress within the cementitious matrix. Standard C1 adhesives lack the deformability to absorb this energy. As a result, the industry is increasingly turning to RDP for tile adhesive to transition from rigid bonding to elastic coupling.

Technical Solution: The Polymer Bridge Mechanism

By integrating specialized Redispersible polymer powder for underfloor heating into the dry-mix mortar, a dual-network structure is formed. While the cement provides the compressive strength, the RDP forms a flexible polymer film that acts as a "bridge" across micro-cracks.

Elasticity Enhancement: RDP significantly lowers the elastic modulus of the mortar, allowing it to move in tandem with the thermal expansion of the floor.

Superior Adhesion to Low-Porosity Surfaces: When bonding granite and ceramic tiles with RDP, the polymer improves the wetting ability of the adhesive, ensuring maximum contact area on non-porous surfaces.

Impact Resistance: The polymer film absorbs mechanical shocks and vibrations, which is critical in high-traffic commercial zones equipped with radiant heating.

Comparative Performance Table:

| Performance Metric (ISO 13007 / EN 12004) | Standard Cementitious Adhesive (C1) | RDP-Modified Flexible Adhesive (C2S1) |

| Transverse Deformation (Flexibility) | < 1.0 mm | > 2.5 mm |

| Adhesion Strength after Heat Aging | 0.45 MPa | 1.35 MPa |

| Open Time (High Temperature) | 10 - 15 min | 30+ min |

| Freeze-Thaw Resistance | Low | High |

Conclusion and Impact:

The transition to S1 and S2 class flexible adhesives, powered by advanced polymer technology, has become the benchmark for luxury flooring. As a specialized RDP chemical manufacturer, we have observed that projects utilizing polymer-modified adhesives report a 95% reduction in long-term maintenance claims related to tile delamination.

Are you optimizing your product line for the booming underfloor heating market? Our laboratory provides comprehensive support for manufacturers seeking to enhance their adhesive performance.

Why partner with us?

Custom Grade Selection: We offer specific Tg (Glass Transition Temperature) variants of RDP to match your local climate and substrate requirements.

Formulation Benchmarking: Send us your current dry-mix, and we will provide a performance-optimized dosage report to help you prevent mortar segregation and cracking.

Direct Factory Supply: As a leading RDP chemical manufacturer, we ensure consistent batch quality and competitive pricing for global distribution.

[Contact Our Engineering Team for a Technical Consultation & Free Sample Kit]