Hydroxypropyl Methyl Cellulose for Wall Putty in Southeast Asia

In Southeast Asian countries such as Indonesia, Vietnam, Thailand, and the Philippines, wall putty and skim coat are widely used in residential and commercial construction. However, due to high temperature, strong sunlight, and variable humidity, manufacturers and contractors often face serious quality issues.

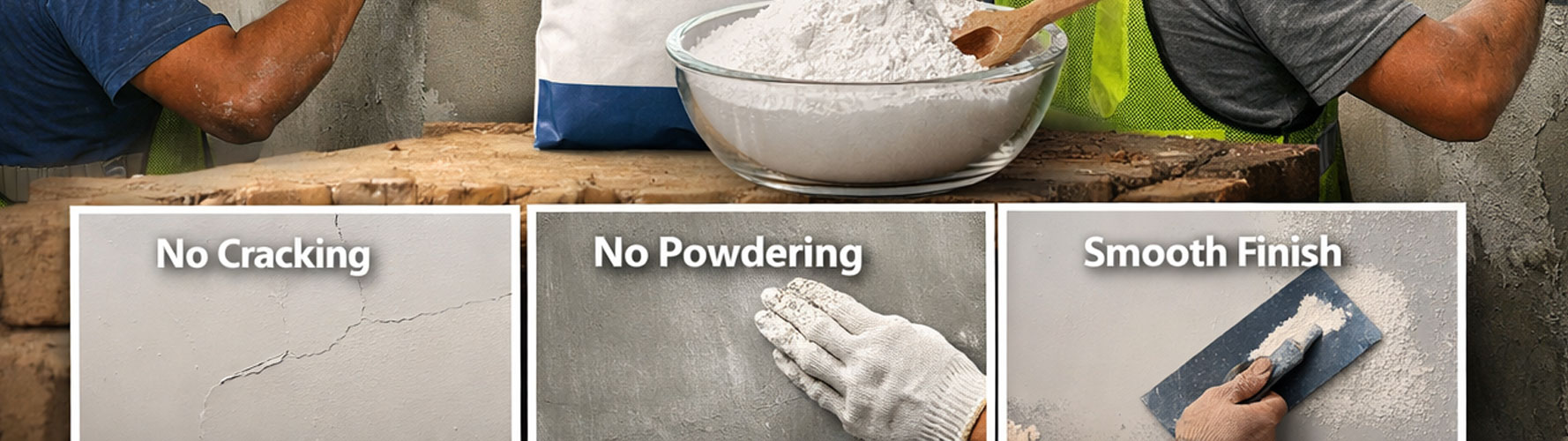

Common problems include:

Cracking caused by rapid water evaporation

Powdering due to insufficient cement hydration

Poor workability, making application slow and inconsistent

To address these challenges, a local wall putty manufacturer introduced Hydroxypropyl Methyl Cellulose for Wall Putty into their formulation.

Project Goal

The objective of this project was to improve both product performance and on-site construction efficiency by using a suitable HPMC for Wall Putty, specifically designed for tropical construction conditions.

Key requirements included:

Strong water retention under high temperature

Smooth and stable workability

Reduced surface defects after drying

Solution: Construction Grade HPMC for Wall Putty & Skim Coat

After formulation trials, the manufacturer selected Construction Grade HPMC as the core functional additive.

Why HPMC Powder for Wall Putty Was Chosen

Excellent water retention to slow evaporation

Stable viscosity for consistent mixing

Good compatibility with cement and fillers

By incorporating HPMC Powder for Wall Putty, the wall putty system became more robust and adaptable to Southeast Asia’s climate.

Performance Improvement with HPMC for Skim Coat

1. Cracking Control in Hot Conditions

Hydroxypropyl Methyl Cellulose for Wall Putty effectively retained moisture during curing, allowing full cement hydration even under strong sunlight.

Result:

Significant reduction in surface cracking

Improved long-term durability for both interior and exterior walls

2. Reduced Powdering and Stronger Surface

Before using HPMC for Wall Putty, the dried surface often showed chalking and dusting.

After optimization with Construction Grade HPMC, surface cohesion improved noticeably.

Result:

Less powdering after drying

Cleaner and stronger wall surfaces

3. Improved Workability and Application Efficiency

By applying HPMC for Skim Coat, contractors experienced smoother spreading and easier troweling.

Result:

No dragging or tearing during application

Better surface flatness

Higher daily construction output

Application Scope

This solution was successfully applied to:

Interior wall putty

Exterior wall putty

Cement-based skim coat systems

In all cases, Hydroxypropyl Methyl Cellulose for Wall Putty played a decisive role in quality improvement.

Customer Feedback

After switching to HPMC Powder for Wall Putty, the manufacturer reported:

Fewer customer complaints

Improved product consistency

Stronger competitiveness in the local market

The optimized formulation allowed the company to position its wall putty products as more stable and construction-friendly, especially for tropical environments.

Conclusion

This Southeast Asia case demonstrates that Hydroxypropyl Methyl Cellulose for Wall Putty is a reliable and effective solution for cracking, powdering, and poor workability in challenging climates.

By choosing the right Construction Grade HPMC and applying it correctly in wall putty and skim coat systems, manufacturers can achieve consistent quality and better construction performance.

For tropical regions, HPMC for Wall Putty and HPMC for Skim Coat are no longer optional additives—they are essential performance enhancers.