News

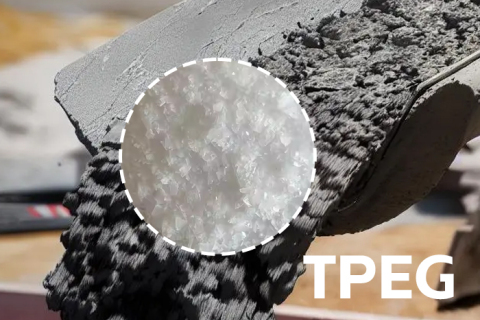

In the construction industry, the performance of concrete directly impacts the quality, lifespan, and cost of buildings. How to enhance the strength, durability, and workability of concrete has always been a focus of the industry. TPEG superplasticizer monomer, as a revolutionary concrete admixture, is bringing innovative solutions to the construction sector with its outstanding performance.

TPEG (Polyether High-Efficiency Water Reducing Agent Monomer) is a new type of water-reducing agent widely used in the construction industry, particularly in the production and application of concrete. TPEG enhances its water-reducing performance and fluidity through chemical modification, making it an essential component of modern concrete technology.

In the construction industry, concrete serves as a fundamental material, and its performance and quality are crucial for the safety and durability of buildings. TPEG Water Reducer Monomer, as a new type of green and eco-friendly material, is bringing revolutionary changes to the construction sector. This article will introduce the characteristics, applications, and advantages of TPEG Water Reducer Monomer in the construction field.

TPEG, as a new type of water reducer monomer, is gradually gaining attention in the construction industry. It possesses excellent water-reducing properties, significantly lowering the water-to-binder ratio of concrete, thereby enhancing its strength and durability.

In the world of construction, achieving the perfect concrete mix is crucial for durability and performance. One of the key components that can significantly improve your concrete's workability and strength is Concrete Superplasticizer Monomer TPEG. This innovative product is designed to meet the demands of modern construction projects, ensuring you achieve superior results every time.

In the modern construction industry, the quality of concrete is crucial as it directly impacts the stability and durability of structures. To enhance concrete performance, TPEG, a new high-efficiency water reducer, has garnered significant attention in the industry. This article will detail the advantages, applications, and real-world cases of TPEG, demonstrating why it is an ideal choice for improving concrete quality.

TPEG (Triphenyl Phosphate Pentyl Ester) monomer, as a high-efficiency concrete superplasticizer, offers significant benefits in the construction industry. It effectively disperses cement particles, reduces concrete hydration heat, and enhances fluidity and workability. The use of TPEG can significantly improve construction efficiency, enhance structural stability, optimize material usage, improve aesthetic quality, and support the sustainable development of the construction industry.

With the continuous development of the global petrochemical and building materials industries, polycarboxylate monomer TPEG, as an important chemical raw material, is increasingly used in the industry, and market demand continues to grow. Recently, industry analysts have conducted in-depth discussions on the development trends of polycarboxylate monomer TPEG and have predicted future market prospects.

1. TPEG has good adaptability to cement. 2. The cost of TPEG is much lower than that of other types of polycarboxylic acid raw materials. 3. With TPEG solid content of 22% and 1.1% concrete content, the water reduction rate can reach more than 30%.

In modern construction projects, concrete is a widely used building material, and its performance directly affects the quality and durability of the project. With the advancement of science and technology, the research and development of concrete additives has become a key way to improve the performance of concrete. Among them, HPEG Polycarboxylate superplasticizer monomer has become a major innovative breakthrough in the field of concrete technology in recent years with its excellent water-reducing performance and the characteristics of improving concrete workability.

In building materials, the use of polycarboxylate superplasticizer monomer can effectively improve the working performance and strength of concrete. However, when using polycarboxylate superplasticizer monomer, we also need to pay attention to some issues to ensure its normal use and effect. Here are some issues to pay attention to:

Slow-release monomers, functional monomers, reactive monomers.