High Viscosity Polyvinyl Chloride Paste Resins

Polyvinyl chloride homopolymer PSM-31 is produced by the microsuspension polymerisation method. It is readily converted into low-viscosity plastisols with an excellent shelf life. PSM-31 pastes have a pseudoplastic rheology at low shear rates and have a dilatants rheology at medium or high shear rates.

- EASTCHEM

- CHINA

- 7 days

- 7000MT per annum

- Information

Description:

Polyvinyl chloride homopolymer PSM-31 is produced by the microsuspension polymerisation method. It is readily converted into low-viscosity plastisols with an excellent shelf life. PSM-31 pastes have a pseudoplastic rheology at low shear rates and have a dilatants rheology at medium or high shear rates.

Performance indexes: (Q/SHG 1-2019)

Item | Specification | |

Resin | Appearance | White powder |

Polymerization degree | 1200-1400 | |

Volatile component, % , ≤ | 0.50 | |

Bulk density, g/cm3 | 0.20-0.40 | |

Residual vinyl chloride monomer, mg/kg ≤ | 5.0 | |

Mixture | B-type viscosity (30oC) mPa ·s Resin: DOP=100:65 12rpm | 2000-4500 |

Scratch granularity, μm, ≤ | 50 | |

Product properties:

-Medium degree of polymerization

-Low viscosity and good shelf life

-Be easy deaeration

-Good foam-forming properties

Applications:

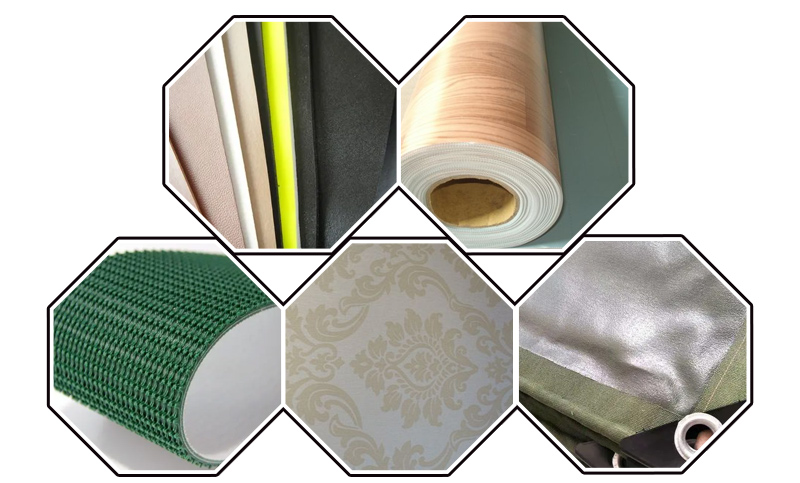

-Foam and non-foaming leather

-Floor leather

-Convey belt

-Dip moulding

-Wallpapers

-Coated fabrics and canvas coating

-Toys and rotational moulding

-Cap mat and casting products

Packing:

20kg three layers of paper bag, or plastic woven bag (20 + 0.2kg).Distinguishing color mark of letter written on bag , PSM-31 type-red.

Store and transport:

It is prevented from moisture, rain, snow and exposure , throwing and other mechanical damage.

About us

Our Advantages

1. The perfect service team provided solutions for differences and differences

2. The rich industry has been tested in several countries all over the world

3. Stable supply chain ensures stable supply of goods

4. High-quality products to provide high-quality materials and chemical products

Honors and qualifications