- Home

- >

- News

- >

- Product News

- >

News

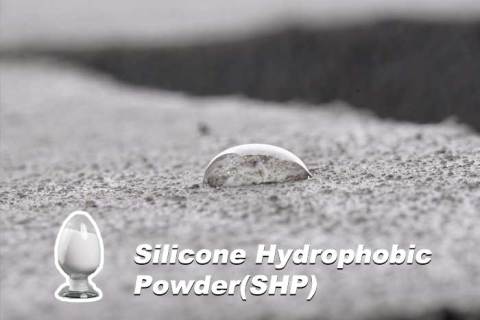

Silicone Hydrophobic Powder (SHP) is an innovative additive designed for the construction industry, enhancing the water-repellent properties of various building materials. Its unique formulation makes it a crucial component for improving durability and performance in construction applications.

HPMC is more than just a water retainer. It's a versatile polymer boosting efficiency and quality in your projects.

Forget focusing solely on steel and concrete! Behind the scenes of modern construction, a crucial material is quietly playing a significant role: PCE Powder (Polycarboxylate Ether Superplasticizer). It may not be as visually prominent as concrete or as robust as steel, but with its unique "invisible strength," PCE Powder empowers construction with limitless possibilities and achieves superior quality.

Forget focusing solely on steel and concrete! Behind the scenes of modern construction, a crucial material is quietly playing a significant role: PCE Powder (Polycarboxylate Ether Superplasticizer). It may not be as visually prominent as concrete or as robust as steel, but with its unique "invisible strength," PCE Powder empowers construction with limitless possibilities and achieves superior quality.

The construction industry has always been a realm that seeks innovation and progress. As consumers demand higher performance from building materials, Redispersible Polymer Powder (RDP) has emerged as a key enabler in upgrading construction materials, thanks to its exceptional capabilities.

Polycarboxylate Superplasticizer Monomer HPEG is a cutting-edge additive designed for the construction industry, enhancing the properties of concrete and cement-based materials. Its remarkable ability to improve the workability and strength of concrete makes it a vital resource for modern building projects.

Polycarboxylate Superplasticizer Monomer HPEG is a high-performance building material additive primarily used in the production of concrete and cement products. It significantly enhances the flowability and strength of concrete, making it an essential component in modern construction.

PCE high range water reducing concrete admixture, particularly the ES4099 with defoaming function, is an important additive in modern concrete technology. Its application range is similar to that of liquid polycarboxylate superplasticizers, making it suitable for various types of concrete and in high market demand.

HPMC (Hydroxypropyl Methylcellulose) is a versatile functional additive widely used in the building materials industry. HPMC's excellent bonding properties, water retention, and workability make it an indispensable component in construction applications. This article will explore the use of HPMC in building materials and analyze how it solves common industry problems.

TPEG (Polyether High-Efficiency Water Reducing Agent Monomer) is a new type of water-reducing agent widely used in the construction industry, particularly in the production and application of concrete. TPEG enhances its water-reducing performance and fluidity through chemical modification, making it an essential component of modern concrete technology.

With the continuous progress of modern construction technology, especially the commercialization of ordinary concrete, the construction industry's demand for concrete is not only limited to strength, but also includes environmental protection, durability, and meeting specific project requirements. In this context, polycarboxylate superplasticizers (PCE), as a new type of admixture, have received widespread attention due to their excellent performance.

In the construction industry, how to provide long-lasting waterproofing protection for building exteriors and foundations has always been a significant challenge. Traditional waterproofing materials such as coatings and sealants often lose their effectiveness over time when exposed to sunlight, wind, and rain. However, a new type of Silicone Water Repellent Powder material can solve this problem for you.