News

This product article highlights the benefits of using High-Quality HPMC Water Retention Agent in gypsum plasters, focusing on its water retention, workability, eco-friendliness, and compatibility with other additives.

PCE Powder (Polycarboxylate Superplasticizer) plays a crucial role in cement grouting and dry mortar, enhancing fluidity, increasing strength, and improving adhesion while reducing costs and environmental impact. Choosing our PCE Powder provides efficient, reliable construction materials, ensuring the quality of your projects.

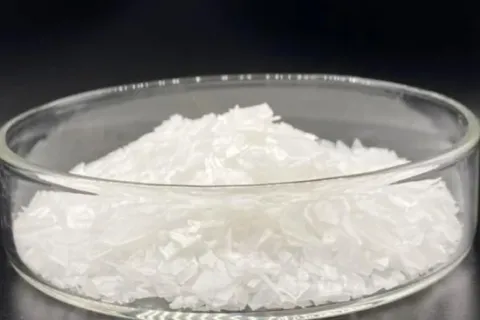

As a leading chemical materials company, we understand the importance of high-performance additives in the construction industry. Our High Quality Water Retention Agent, Hydroxypropyl Methylcellulose (HPMC), is specifically formulated to enhance the performance of gypsum plasters. This article will explore the unique benefits of HPMC, its applications, and why you should choose our product for your construction needs.

In the modern construction industry, the quality of concrete is crucial as it directly impacts the stability and durability of structures. To enhance concrete performance, TPEG, a new high-efficiency water reducer, has garnered significant attention in the industry. This article will detail the advantages, applications, and real-world cases of TPEG, demonstrating why it is an ideal choice for improving concrete quality.

Polycarboxylate superplasticizer monomer HPEG is a cutting-edge solution designed to significantly improve concrete performance. HPEG is outstandingly cost-effective, delivering high water reduction rates at minimal usage, resulting in stronger, more durable concrete.

In the construction industry, the quality of concrete determines the longevity and stability of the structure. Facing increasingly stringent engineering requirements, traditional concrete additives are no longer able to meet the demand. Fortunately, polycarboxylate super plasticizer powder (PCE) emerged at the historic moment, bringing unprecedented changes.

On August 31, 2024, EASTCHEM will celebrate its 12th anniversary. Over the past twelve years, we have consistently adhered to our mission of “Chemistry Makes the World Better,” demonstrating our commitment to customers, society, and employees through continuous innovation and excellent service. Looking ahead, EASTCHEM will remain dedicated to advancing the industry, earning societal respect, and ensuring employee well-being. We firmly believe that through sustained innovation and outstanding execution, we will achieve more breakthroughs and accomplishments, contributing greater value to global customers and society.

Emulsion Grade White Powder Polyvinyl Chloride (PVC Paste Resin) has extensive applications in the building sector, including in foam leathers, wallpapers, the foam layer of elastic floors, and coated fabrics and canvas coatings. Its superior properties such as softness, durability, water resistance, and abrasion resistance make it a crucial component in building materials. The use of PVC Paste Resin not only enhances the functionality of materials but also improves the aesthetics and comfort of buildings.

Hydroxypropyl methylcellulose (HPMC) is a chemically modified cellulose polymer widely used in building materials. Its primary functions include enhancing the performance of mortars and cement, improving construction quality, and offering environmental benefits.

Polycarboxylate Superplasticizer Powder (PCE) has become increasingly important in modern construction due to its ability to significantly enhance concrete performance. PCE powder improves concrete flowability, reduces cement usage, and increases strength and durability. Its applications span high-strength concrete, self-consolidating concrete, precast components, and repair projects. For optimal results, precise measurement and proper storage conditions are essential. PCE continues to play a vital role in construction, offering cost-effective and efficient solutions.