- Home

- >

News

VAE Re-dispersible Polymer Powder is dispersed in the gypsum slurry and then forms a film, filling the pores of the slurry and intersecting with the gypsum hydration products to form a three-dimensional network structure, making the gypsum structure more dense.

The compatibility between polycarboxylate polymer powder and cement is not good, and the concrete mixture is prone to problems such as segregation, bleeding, increased slump loss, and shortened setting time. This makes the concrete mixture unable to be transported and poured normally, reducing the strength of the concrete. and durability.

VAE Re-dispersible Polymer Powder is a water-soluble re-dispersible powder, a copolymer of ethylene and vinyl acetate, with polyvinyl alcohol as a protective colloid.

VAE Re permeable Polymer Powder as a powder adhesive, is widely used in the construction industry. The quality of dispersible latex powder is directly related to the quality and progress of construction. With the rapid development of the domestic building energy-saving market With the development of VAE Re-dispersible Polymer Powder, more and more companies are involved in the research and development and production of VAE Re-dispersible Polymer Powder products, and users have more and more choices.

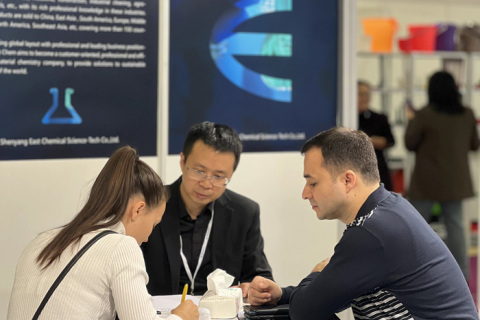

On October 31, the 26th Russian International Chemical Exhibition (KHIMIA 2023) successfully opened at the Expo Center Exhibition Hall in Moscow, Russia. As one of the most prestigious chemicals trade shows, this exhibition attracted the participation of many manufacturers in the industry . At the same time, this is also the first appearance of EAST CHEM at the Russian International Chemical Exhibition.

VAE Re-dispersible Polymer Powder should not be put in at one time, but should be weighed in batches to find the right amount.

VAE Re permeable Polymer Powderhas been widely used in fields where inorganic cementitious materials need to be modified, such as single component JS waterproof coatings, polystyrene board bonding mortar for building insulation, flexible surface protection mortar, polystyrene particle insulation coatings, ceramic tile adhesives, self-leveling mortar, dry mix mortar, putty, etc. Adding VAE Re permeable Polymer Powder to putty powder can increase its strength, have strong adhesion and mechanical properties, and greatly help improve hardness. It has good waterproof and permeability, as well as excellent alkali resistance and wear resistance. It can also improve water retention, increase opening time, and enhance durability.

VAE Re-dispersible Polymer Powder products are water-soluble redispersible powders, which are divided into ethylene/vinyl acetate copolymers, vinyl acetate/ethylene tertiary carbonate copolymers, copolymers, etc., and are powder adhesives made after spray drying , vae powder application scope is extremely wide. Chinese name, redispersible latex powder, belongs to water-soluble redispersible powder. include. Ethylene/vinyl acetate copolymer, features, water resistance, workability. Performance characteristics: Vae copolymer rdp has extremely outstanding bonding strength, giving the mortar excellent alkali resistance. In addition to the adhesion, flexural strength, waterproofness, plasticity, wear resistance and construction properties of the mortar, vae emulsion application fields include ceramic tile adhesive. Bonding agent, bonding mortar for exterior wall insulation system, plastering mortar for exterior wall insulation system, ceramic tile grouting agent. Self-flowing cement mortar.

Polycarboxylate polymer powder is a variety of polymer organic compounds mainly composed of polycarboxylates, which have good water reducing performance. Polycarboxylic acid high-performance water reducing agent in powder form is much more convenient from transportation to customer use, and since then, the powder has formed the development trend of such products.

Re-dispersible Polymer Powder is a widely used material in various fields. Here are some examples of the application of redispersible latex powder in daily life:

The addition of water reducing agents can effectively reduce the amount of cement used in concrete, reduce the self weight of concrete, reduce the burden of construction, and reduce losses during the construction process.

External wall insulation is composed of polymer mortar, glass fiber mesh cloth, flame-retardant molded polystyrene foam board (EPS) or extruded board (XPS) and other materials, which are bonded on site