- Home

- >

News

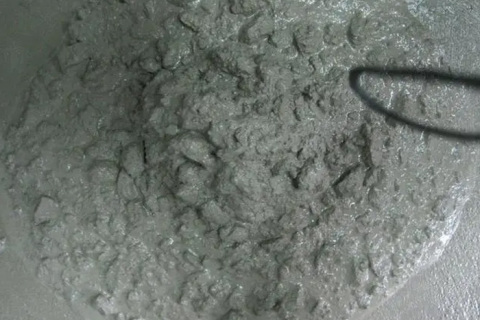

Cement mortar: hpmc improve the dispersion of cement sand, greatly improve the plasticity and water retention of mortar, have an effect on preventing cracks and enhance the strength of cement.

Under the condition that the slump of concrete is basically the same, the admixture of mixing water can be reduced. According to the size of its water-reducing rate, it can be divided into ordinary water-reducing agent, high-efficiency water-reducing agent and high-performance water-reducing agent.

The common description of the performance of Polycarboxylic Superplasticizer is: high water reduction rate, very good adaptability to cement, good workability of concrete, no loss of slump in one hour, etc. In fact, the composition of cementitious materials is complex and changeable. From the perspective of adsorption dispersion mechanism, any admixture can not adapt to all situations.

From June 19th to 20th, the 37th International Fine and Specialty Chemicals Exhibition was held at the Düsseldorf Exhibition Center in Germany, attracting representatives from the global chemical and materials industries. As a company focusing on chemicals and materials, East Chemicals showcased its unique solutions at the exhibition with high-performance chemicals and advanced materials as its main line.

CPhI North America 2024 will be held in Philadelphia, USA from May 07-09. As the world's top professional exhibition for the pharmaceutical industry, CPHI North America is the only pharmaceutical industry event in the United States that covers the entire industry chain including drug research and development, production, and packaging.

On April 29, the three-day 16th Chongqing International Battery Technology Forum/Exhibition (CIBF2024) concluded successfully at the Chongqing International Expo Center. During this period, East Chemical shined at the venue with its hard-core products, providing one-stop solutions for chemical raw material manufacturers.

Polycarboxylate ether superplasticizer (PCE) has high blending capacity and high water reduction rate (>40%), which can significantly improve the workability, mechanical properties and durability of concrete. It has become high performance or ultra high performance. One of the important components of concrete mix design.

We are very pleased to announce that the International Trade Department of East Chemical has moved to a new office location and is taking this opportunity to start a new journey.

Polycarboxylate Superplasticizer Powder adopts a new synthetic preparation process. The water reduction rate of polycarboxylate polymer powder is as high as more than 40%. It can be used in mortars of various cement gelling formula systems and gypsum gelling formula systems. Polycarboxylate ether superplasticizer can give mortar products excellent The working performance and flow performance can significantly improve the quality of cement-based materials and gypsum-based materials.

As a new type of water-reducing agent after naphthalene-based, melamine-based, aliphatic-based and sulfamate-based water-reducing agents, polycarboxylic acid-based water-reducing agents have been widely used in many important projects due to their many unique performance advantages.

The compatibility between polycarboxylate polymer powder and cement is not good, and the concrete mixture is prone to problems such as segregation, bleeding, increased slump loss, and shortened setting time. This makes the concrete mixture unable to be transported and poured normally, reducing the strength of the concrete. and durability.