- Home

- >

News

Due to the low softening point, ordinary polycarboxylate superplasticizers cannot be powdered by spray drying. Molecular design to increase softening point without losing water-reducing performance yields high-content powdered polymers.

1. Polycarboxylate Superplasticizer Powder adjusts the water consumption or sand ratio through experiments according to the concrete design requirements to reach the required water reducer dosage of slump, strength and setting.

Polycarboxylate superplasticizer is a new generation friendly environmental superplasticizer. It is a concentrated product, best high water reduction, high slump retention ability, low alkali content for the product, and it having high strength gained rate.It can be widely used in premix of common concrete, gushing concrete, high strength and durability concrete. Especially! It can be used in high strength and durability concrete having excellent capability .

Polycarboxylate water-reducing agents has the properties of high water reduction and high slump retention, and can impart high strength and durability to concrete. It has shown outstanding advantages in high-quality projects such as national large-scale water conservancy, nuclear power, and bridges. Compared with naphthalene-based water-reducing agents, polycarboxylate water-reducing agents are sensitive to the mud content of sand and gravel aggregates [1-3] and are expensive. Therefore, in laboratories and engineering construction, attempts have been made to mix polycarboxylate water-reducing agents and naphthalene-based water-reducing agents to take advantage of their respective advantages.

Due to its excellent properties, polycarboxylate superplasticizers are widely used in many fields, including:

Polycarboxylate polymer powder olycarboxylic acid powder breaks the convention in the production process and adopts thermal synthesis process, which can reduce production costs in terms of energy consumption. No release agent is added, and the purity of the produced products is higher, with the solid content controlled at around 98%. In terms of product performance, high-purity products have the characteristics of low dosage, high active ingredients and good collapse-preserving properties, further reducing customer costs.

Generally speaking, the higher the water reducing rate of water reducing agent is, the more sensitive the mixing logistics mobility is to the content in its effective content range.

Polycarboxylate Superplasticizer Powder adopts a new synthetic preparation process. The water reduction rate of polycarboxylate polymer powder is as high as more than 40%. It can be used in mortars of various cement gelling formula systems and gypsum gelling formula systems. Polycarboxylate ether superplasticizer can give mortar products excellent The working performance and flow performance can significantly improve the quality of cement-based materials and gypsum-based materials.

The compatibility between polycarboxylate polymer powder and cement is not good, and the concrete mixture is prone to problems such as segregation, bleeding, increased slump loss, and shortened setting time. This makes the concrete mixture unable to be transported and poured normally, reducing the strength of the concrete. and durability.

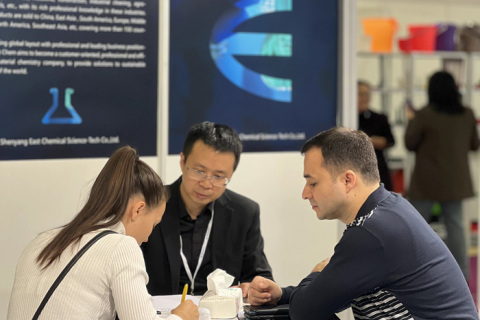

On October 31, the 26th Russian International Chemical Exhibition (KHIMIA 2023) successfully opened at the Expo Center Exhibition Hall in Moscow, Russia. As one of the most prestigious chemicals trade shows, this exhibition attracted the participation of many manufacturers in the industry . At the same time, this is also the first appearance of EAST CHEM at the Russian International Chemical Exhibition.

Polycarboxylate polymer powder is a variety of polymer organic compounds mainly composed of polycarboxylates, which have good water reducing performance. Polycarboxylic acid high-performance water reducing agent in powder form is much more convenient from transportation to customer use, and since then, the powder has formed the development trend of such products.

The addition of water reducing agents can effectively reduce the amount of cement used in concrete, reduce the self weight of concrete, reduce the burden of construction, and reduce losses during the construction process.