- Home

- >

News

Lithium silicate is an emerging positive electrode material for lithium-ion batteries, which has excellent characteristics such as high energy density, high voltage platform, and long cycle life. Compared with traditional lithium cobalt oxide and lithium manganese oxide, lithium silicate has obvious advantages in energy density, safety and cost, and has become the first choice for new energy vehicles and large energy storage systems.

Lithium silicate improves performance of natural hydraulic lime-based mortars By pre-treating the natural hydraulic lime-based mortar by impregnating it with lithium silicate solution and spraying it on the surface, its compressive strength, surface hardness and freeze-thaw cycle resistance are significantly improved. This approach offers new ways to improve the performance of building materials.

lithium silicate as a versatile inorganic compound, is gradually changing the future of the construction industry. With its excellent performance and environmentally friendly characteristics, lithium silicate is widely used in architectural coatings, concrete additives and thermal insulation materials. This article will explore the application of lithium silicate in the construction industry and look forward to its potential impact on the development of the industry.

is a compound formed by the structure and formation of metallic lithium and silicate radicals. The trade name is lithium water glass. Most of them use the lithium hydroxide method to react sodium silicate with sulfuric acid to generate hydrated silicic acid and sodium sulfate. The hydrated silicic acid reacts with lithium hydroxide to generate lithium silicate and water to prepare lithium silicate products.

Concrete is a common building material. Its compressive strength and tensile strength can directly affect the stability and safety of the building structure. In recent years, research has shown that lithium silicate can effectively improve the strength of concrete materials. This article will discuss the impact of lithium silicate on concrete strength.

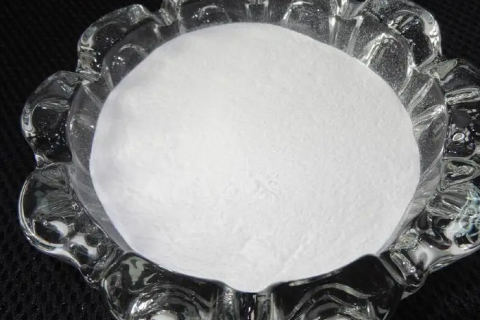

lithium silicon (Li2SiO3) is a colorless or white crystal powder with the following basic characteristics:

Dust on concrete floors, generated by regular traffic or low-quality construction, is a common problem in the industrial sector. The cement component is constantly subject to wear and tear, eventually causing large particles of aggregate to loosen on the surface of the concrete. This not only makes the floor unsightly, but also causes great harm to people and property.

lithium metasilicate is a colorless, tasteless, non-toxic and odorless solid with good chemical and thermal stability. Concrete using lithium silicate as an additive is widely used in engineering structures to enhance concrete strength, improve concrete properties, and improve durability.

1. Advantages of lithium silicate Lithium silicate is a multifunctional coating additive that offers the following benefits: 1. Enhance adhesion: Lithium silicate can enhance the adhesion between the paint and the substrate, making the paint adhere more firmly to the surface of the substrate.

The main function of lithium silicate in cement is to enhance the crack resistance and wear resistance of cement concrete. Lithium silicate is called "concrete sealant", which can penetrate deeply into concrete and react with lime in concrete to form water-insoluble hydraulic stone, which can increase the density of concrete and reduce the occurrence of surface cracks. . In addition, lithium silicate can also reduce wear on the concrete surface and increase the hardness and strength of the concrete, thereby extending the service life of the concrete structure. Therefore, the addition of lithium silicate is an effective way to improve the performance of concrete.

Silicate treatments can be used to improve the properties of concrete surfaces. Higher abrasion and chemical resistance will especially extend the service life of concrete floors.