- Home

- >

News

Hydroxypropyl Methyl Cellulose) is a water-soluble polymer compound commonly used in construction materials, medicine, food, cosmetics and other fields. Here are some details about the use of HPMC

Hydroxypropyl methyl cellulose can be used as a part of the detergent, such as the formula (mass fraction) is: 5%~60% water soluble surfactant, 0.01%~10%HPC, 0~10% water soluble polyols, 0.01%~5% cationic polymeric skin conditioner and water. The product showed good performance, including gentleness, skin humidification, desirable rheology and application characteristics, good rinsing and product stability.

Chemspec Europe 2023 With a highly specialised profile, Chemspec Europe is a key event for the fine and speciality chemicals industry.

Hydroxypropyl methyl cellulose has a wide range of uses in our daily life. It not only plays an obvious role in construction, but also occupies a great position in the paint industry. Let's look at hydroxypropyl methyl cellulose. It has four characteristics:

Hydroxypropyl methyl cellulose, is a nonionic cellulose mixed ether. It is a semi-synthetic, inactive, viscoelastic polymer commonly used as a lubricant in ophthalmology, or as an excipient or excipient in oral medicine.

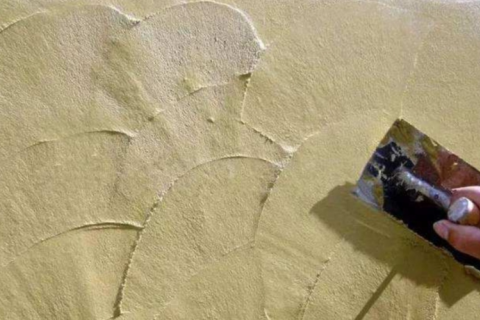

In recent years, with the continuous development of external insulation technology, hydroxypropyl methyl cellulose production technology progress, as well as hydroxypropyl methyl cellulose HPMC itself has excellent characteristics, hydroxypropyl methyl cellulose HPMC in the construction industry has been widely used. In order to investigate the interaction mechanism between HPMC and cement-based materials, this paper focuses on the improvement effect of HPMC on the cohesion of cement-based materials.

High-quality HPMC can be evenly and effectively dispersed in cement mortar and gypsum based products, and wrap all solid particles, and form a layer of wetting film. The moisture in the base is gradually released over a long period of time, and hydrates with inorganic cementitious materials, thus ensuring the bonding strength and compressive strength of the materials. Therefore, in high temperature summer construction, in order to achieve the water retention effect, it is necessary to add enough high-quality HPMC products according to the formula, otherwise, quality problems such as insufficient hydration, strength reduction, cracking, hollowing and falling off caused by drying too fast will occur, and the construction difficulty of workers will also be increased. As the temperature decreases, the amount of HPMC can be gradually reduced, and the same water retention effect can be achieved.

Standing at the end of the year, we look back at the past, and there are too many moving and stories in the past. Standing at the beginning of the year, we look forward to the future and have more expectations and dreams in the future.

Enhance the adhesion with the masonry surface, and can enhance the water retention, so that the strength of mortar can be improved. Improve the lubricity and plasticity to improve the construction performance, save time and improve the cost efficiency.