- Home

- >

News

HPMC with uniform reaction, methoxy and hydroxypropyl groups are uniformly distributed, and the water retention rate is high.

Excellent temperature stability: As a non-ionic thickener, the viscosity of HPMC-thickened surfactant system is relatively stable with temperature changes, while the system adding Nacl as a thickener will have a jelly phenomenon at low temperatures.

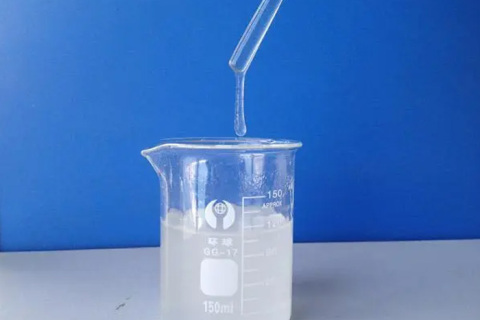

HPMC cellulose is a synthetic polymer chemically modified from natural cellulose. It is composed of part of the hydroxypropylmethyl (Hypromellose) groups in the natural polymer chain of cellulose. This compound is a white to off-white powder with good solubility in water to form a transparent colloidal solution.

1. The visual state of pure HPMC is fluffy and the bulk density is small, ranging from 0.3-0.4g/ml; the adulterated HPMC has better fluidity and heavier hand feel, which is obviously different from the original appearance.

In ready-mixed mortar, the addition amount of HPMC is very low, but it can significantly improve the performance of wet mortar and is a major additive that affects the construction performance of mortar. Reasonable selection of cellulose ethers of different varieties, different viscosities, different particle sizes, different viscosity degrees and added amounts will have a positive impact on improving the performance of dry mortar.

Interior wall putty powder generally has a viscosity of 100,000. Cement mortar has higher requirements for adjustment, and a viscosity of 150,000 is easy to use. In addition, the most critical function of HPMC is to lock in water, followed by thickening.

Hydroxypropyl Methyl Cellulose (hereinafter referred to as HPMC) can be divided into instant type and slow-soluble type. Instant hydroxypropyl methylcellulose HPMC refers to the surface treatment using cross-linking agent during the production process, so that HPMC can be dissolved in cold water.

The 26th Russian International Chemical Exhibition (KHIMIA 2023) will be held from October 30 to November 2, 2023 at the Expo Center Exhibition Hall in Moscow, Russia.

Whiteness: Although whiteness cannot determine the usability of HPMC, the addition of whitening agents during the production process can affect its quality. However, most good products have good whiteness.

Hydroxypropyl methyl fiber (HPMC) is a water soluble polymer, which is commonly used to prepare capsules, tablets, cream, etc. in medicine, food and cosmetics. The following are some dissolution methods for hydroxypropyl methyl fibers:

Building materials: HPMC can be used as an additive for building materials, such as mortar, gypsum board, ceramic tile adhesive, etc. It can improve the adhesion, ductility, and water resistance of materials. Wall coatings: HPMC can be used as a thickener and humectant for wall coatings, improving their viscosity, leveling, and adhesion.