- Home

- >

News

Interior wall putty powder generally has a viscosity of 100,000. Cement mortar has higher requirements for adjustment, and a viscosity of 150,000 is easy to use. In addition, the most critical function of HPMC is to lock in water, followed by thickening.

In this golden shopping season, we sincerely invite you to join our big family and enjoy a grand shopping feast together. As a company committed to providing quality products and services to our customers, we understand our customers' needs and expectations. On this special day, we have prepared a series of discounts for you, so that you can enjoy shopping while saving money and effort.

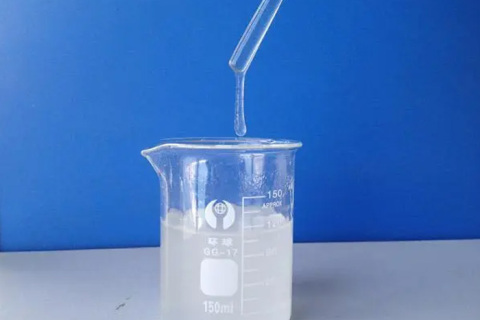

Hydroxypropyl Methyl Cellulose (hereinafter referred to as HPMC) can be divided into instant type and slow-soluble type. Instant hydroxypropyl methylcellulose HPMC refers to the surface treatment using cross-linking agent during the production process, so that HPMC can be dissolved in cold water.

Cellulose is a compound widely used in the chemical and pharmaceutical industries.

The 26th Russian International Chemical Exhibition (KHIMIA 2023) will be held from October 30 to November 2, 2023 at the Expo Center Exhibition Hall in Moscow, Russia.

The main raw material of HPMC is plant fiber, and its price is directly influenced by the supply and demand of plant sources. Seasonal and climate change factors may also have an impact on raw material prices.

About the use of hydroxypropyl methyl cellulose, hydroxypropyl methyl cellulose can be applied to various fields of building materials. The editor will explain the functions and effects of hydroxypropyl methyl cellulose one by one. Next, let's learn the following knowledge together with the editor~

Whiteness: Although whiteness cannot determine the usability of HPMC, the addition of whitening agents during the production process can affect its quality. However, most good products have good whiteness.

Hydroxypropyl methyl fiber (HPMC) is a water soluble polymer, which is commonly used to prepare capsules, tablets, cream, etc. in medicine, food and cosmetics. The following are some dissolution methods for hydroxypropyl methyl fibers:

Building materials: HPMC can be used as an additive for building materials, such as mortar, gypsum board, ceramic tile adhesive, etc. It can improve the adhesion, ductility, and water resistance of materials. Wall coatings: HPMC can be used as a thickener and humectant for wall coatings, improving their viscosity, leveling, and adhesion.

External wall insulation is composed of polymer mortar, glass fiber mesh cloth, flame-retardant molded polystyrene foam board (EPS) or extruded board (XPS) and other materials, which are bonded on site