- Home

- >

News

This product article highlights the benefits of using High-Quality HPMC Water Retention Agent in gypsum plasters, focusing on its water retention, workability, eco-friendliness, and compatibility with other additives.

As a leading chemical materials company, we understand the importance of high-performance additives in the construction industry. Our High Quality Water Retention Agent, Hydroxypropyl Methylcellulose (HPMC), is specifically formulated to enhance the performance of gypsum plasters. This article will explore the unique benefits of HPMC, its applications, and why you should choose our product for your construction needs.

In the modern construction industry, the quality of concrete is crucial as it directly impacts the stability and durability of structures. To enhance concrete performance, TPEG, a new high-efficiency water reducer, has garnered significant attention in the industry. This article will detail the advantages, applications, and real-world cases of TPEG, demonstrating why it is an ideal choice for improving concrete quality.

Polycarboxylate superplasticizer monomer HPEG is a cutting-edge solution designed to significantly improve concrete performance. HPEG is outstandingly cost-effective, delivering high water reduction rates at minimal usage, resulting in stronger, more durable concrete.

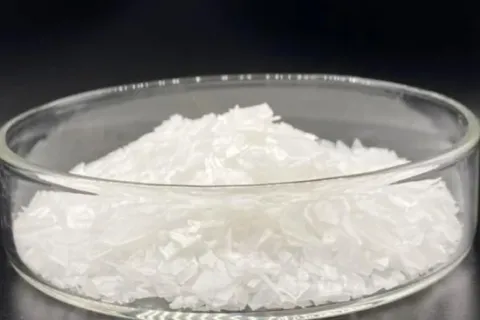

Hydroxypropyl methylcellulose (HPMC) is a chemically modified cellulose polymer widely used in building materials. Its primary functions include enhancing the performance of mortars and cement, improving construction quality, and offering environmental benefits.

Hydroxypropyl Methylcellulose (HPMC) serves as a high-performance building material modifier that plays a crucial role in the construction industry. Its outstanding adhesive properties, rheological property adjustment, and water resistance make it widely used in products such as cement mortar, tile adhesives, and coatings. By enhancing adhesion, improving water resistance, and adjusting rheological characteristics of building materials, HPMC brings innovation to the construction sector, establishing itself as an indispensable material.

Polycarboxylic acid series high-performance water reducing agent is a new generation of high-performance water reducing agent appearing at home and abroad in recent years. Compared with naphthalene series and other traditional superplasticizers, polycarboxylic acid series high-performance superplasticizers have many unique technical performance advantages:

With the development of the modern construction industry, concrete technology continues to advance. Among them, HPEG as a new type of high-efficiency water-reducing agent, has attracted widespread attention due to its unique performance and environmental protection characteristics. This article will explore the use of polycarboxylate superplasticizer monomers in the construction industry and the benefits they bring.

1. Polycarboxylate Superplasticizer Powder adjusts the water consumption or sand ratio through experiments according to the concrete design requirements to reach the required water reducer dosage of slump, strength and setting.

HPEG adopts highly active catalyst and special synthesis process, with light appearance, accurate molecular weight, white appearance, narrow molecular weight distribution, low glycol content and high double bond retention.

High-efficiency water reducer product overview High-efficiency water reducer is an important concrete additive, which can effectively reduce the water-cement ratio of concrete, thereby improving the strength and durability of concrete. Compared with traditional water reducers, high-efficiency water reducers have the following advantages:

Effect of water consumption on performance of polycarboxylic acid water reducer The influence of water consumption of polycarboxylic acid water reducer is very obvious. In the practical application of concrete engineering, sometimes if the water consumption increases by 1~3kg/m3, the concrete will show serious bleeding, resulting in pitting, sanding, holes and other defects on the concrete surface. The uniformity of concrete pouring and construction quality cannot be guaranteed, resulting in the reduction of the strength and durability of the concrete structure.